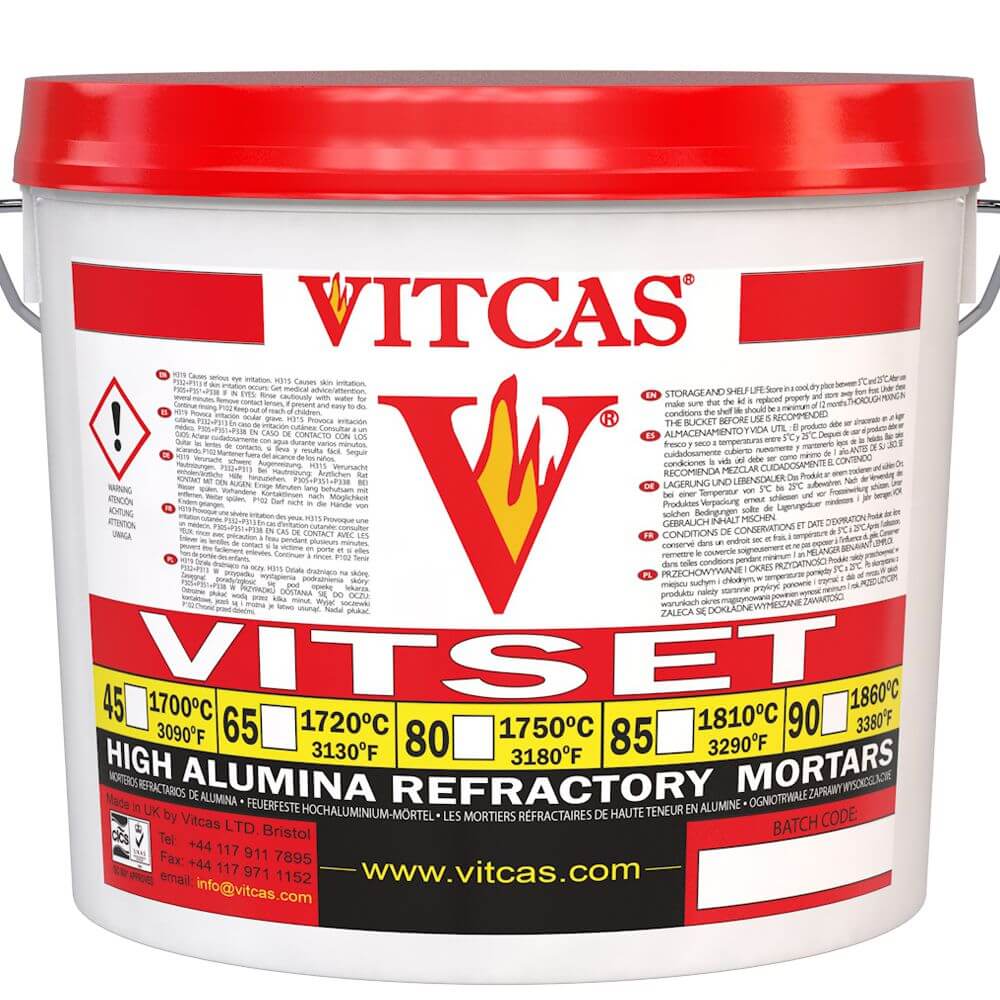

High alumina refractory mortars

Refractory mortars with high alumina content for extreme-temperature applications

Vitset ready mixed high alumina refractory cements and mortars are specially formulated for jointing, coating, and patching in a wide range of high-temperature industrial applications. Designed to perform in temperatures ranging from 1450°C (2640°F) to 1860°C (3380°F), these air-setting mortars offer excellent bonding properties both at ambient temperatures and during service. The recommended mortar bed thickness for jointing firebricks is 3 mm, ensuring optimal mechanical strength and thermal performance.

Vitset 45 - High-Temperature Refractory Mortar

Vitset 45 is an air-setting, ready-to-use refractory mortar suitable for trowelling, patching, and jointing in high-temperature environments up to 1700°C / 3100°F. It forms a strong, air-set bond with all grades of refractory bricks and is also suitable for bonding ceramic fibre materials. The easy-to-apply consistency makes it ideal for both new installations and maintenance work.

Examples of Applications: Vitset 45 is widely used in the setting and repair of dense firebricks, high-temperature insulation bricks, and ceramic fibre blankets, boards, and modules. Common industrial uses include:

- Foundry ladles

- Foundry furnaces

- Rotary cement kilns

- Ceramic kilns and kiln cars

Available in our online store: Vitset 45 - Refractory Mortar, Ready Mixed

| Product | Maximum Service Temperature | Bond Type | Chemical Analysis (%) | |

| Al2O3 | Fe2O3 | |||

| VITSET 45 | 1700°C / 3100°F | Air setting | 44.2 | 0.7 |

Vitset 80 - High Alumina Refractory Mortar for Steel and Foundry Applications

Vitset 80 is a ready mixed, air-setting refractory mortar suitable for setting all grades of refractory bricks. It can also be supplied in a thinner consistency for brick dipping, coating, and spraying applications. Vitset 80 forms a robust air-set bond that is slightly expansile at 1540°C, ensuring tight joints without shrinkage. It exhibits excellent resistance to slag attack and maintains structural stability at temperatures up to 1750°C / 3180°F.

Examples of Applications: Vitset 80 is widely used in steelworks and foundries, particularly in applications where high temperature and chemical attack resistance are essential. Typical uses include:

- Setting high alumina bricks in safety linings of pouring ladles

- Setting bricks and purging nozzles in continuous casting tundishes

- Rendering or dipping in refractory installations exposed to aggressive slag environments

| Product | Maximum Service Temperature | Bond Type | Chemical Analysis (%) | |

| Al2O3 | Fe2O3 | |||

| VITSET 80 | 1750°C / 3180°F | Air setting | 74.0 | 1.3 |

Vitset 85

Ready mixed high alumina refractory mortar with maximum service temperature of 1810ºC. Suitable for higher temperature alloys and treatment vessels.

| Product | Maximum Service Temperature | Bond Type | Chemical Analysis (%) | |

| Al2O3 | Fe2O3 | |||

| VITSET 85 | 1810°C / 3290°F | Air setting | 81.0 | 0.7 |

Vitset 90 - High Purity Refractory Mortar for Specialised Applications

Vitset 90 is a ready mixed, high alumina refractory mortar formulated for high-purity, high-refractoriness applications. Engineered for exceptional thermal stability and performance at elevated temperatures up to 1860ºC / 3380°F, it is particularly suited for use with alumino-silicate and magnesite refractories. This mortar is designed for demanding industrial environments where superior bonding strength and chemical resistance are essential.

Examples of Applications: Vitset 90 is ideal for specialised installations and maintenance in high-temperature settings, including:

- Setting sliding gate plates

- Securing purging nozzles

- Bonding pre-cast refractory shapes

Its combination of purity, strength, and thermal resilience makes it a reliable choice in steelworks, foundries, and other high-performance refractory systems.

Available in our online store: Vitset 90 - High Alumina Refractory Mortar

| Product | Maximum Service Temperature | Bond Type | Chemical Analysis (%) | |

| Al2O3 | Fe2O3 | |||

| VITSET 90 | 1860°C / 3380°F | Air setting | 88.0 | 0.1 |