Heat resistant materials for fireplaces & stoves

Heat Resistant Materials for Fireplaces & Stoves - Solutions for High-Temperature Heating Appliances

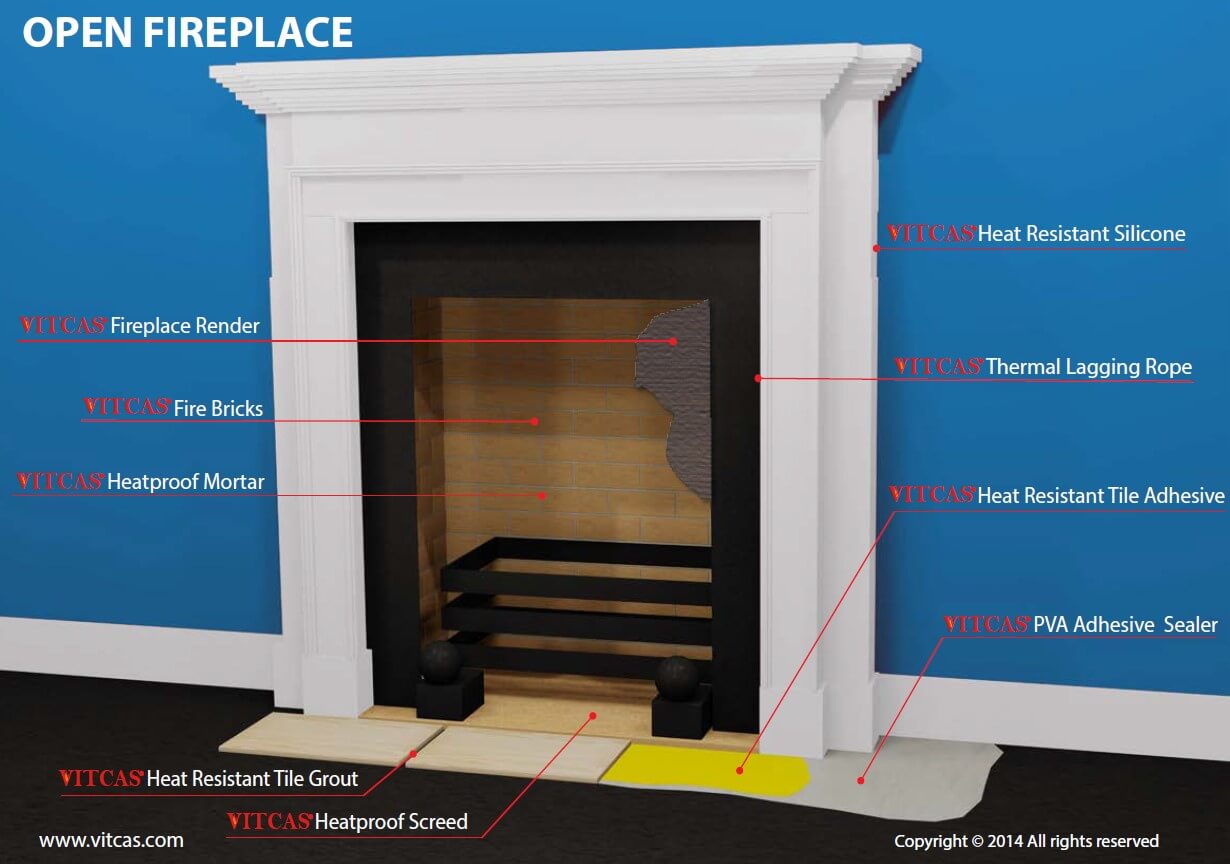

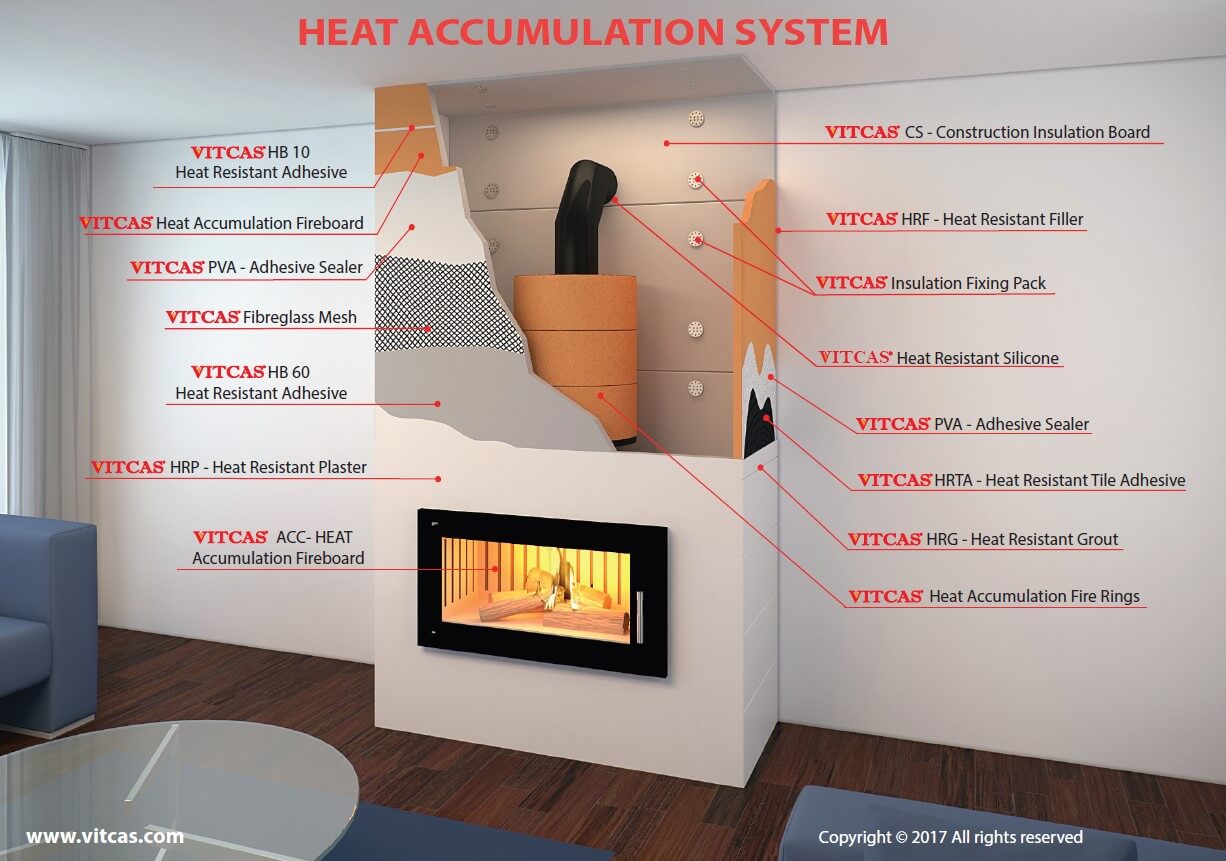

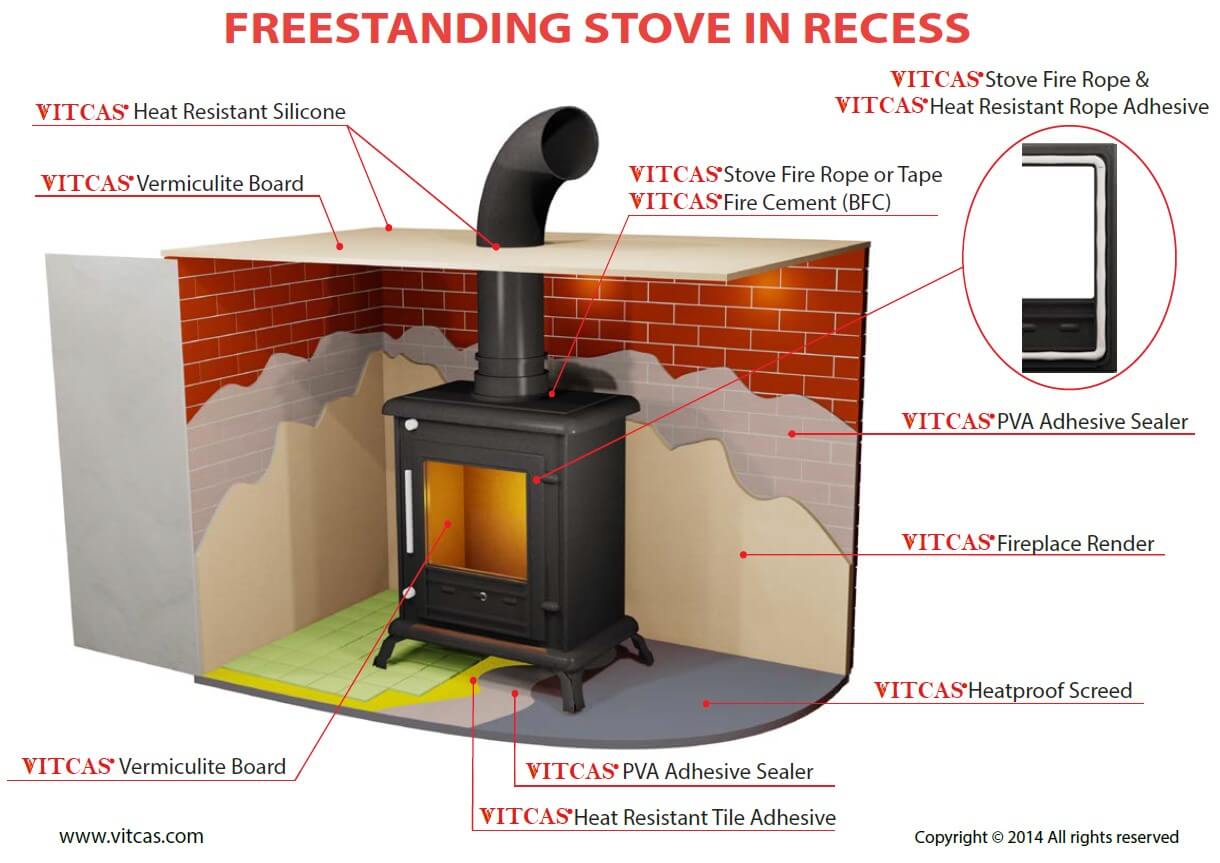

Vitcas offers a comprehensive range of high-performance, heat resistant materials designed specifically for use in fireplaces, log burners, multi-fuel stoves, tiled stoves, range cookers, chimineas, and other solid fuel heating systems. Engineered to withstand extreme temperatures up to 1400°C, these materials are essential for safe construction, repair, and maintenance of heating appliances exposed to direct flame and intense heat.

The Vitcas product range includes high-temperature adhesives, fire cements, refractory mortars, rope sealants, heat resistant paints, heat resistant plaster, fireplace render, insulating boards, and fire bricks - all developed to ensure thermal stability, energy efficiency, and long-term performance. Whether you're sealing flue joints, setting fire bricks, insulating the combustion chamber, or repairing firebacks, Vitcas products deliver reliability and ease of application in both residential and commercial fireplace and stove installations.

Heat resistant materials are suitable for professionals working in stove manufacturing, fireplace installation, heating system maintenance, and fire protection industries. Vitcas supports the full lifecycle of heating systems - from original assembly through installation, maintenance, and refurbishment.

Key Features and Benefits

- High temperature resistance - Rated for continuous use in environments up to 1400°C

- Thermal insulation and heat reflection - Improves efficiency and safety of fireplaces and stoves

- Gas- and smoke-tight sealing - Prevents fume leakage and enhances appliance performance

- Ready-to-use formulations - Many products supplied pre-mixed for easy application

- Strong mechanical and chemical stability - Withstands thermal cycling, soot, ash, and combustion residues

- Compatible with fire bricks, steel, cast iron, and insulation components

Applications

- Jointing and setting fire bricks in stove chambers and fireplace surrounds

- Sealing metal-to-metal connections in flue pipes and stove bodies

- Insulating stove walls, backs, and hearths with vermiculite or calcium silicate boards

- Replacing or repairing rope seals in stove doors and glass panels

- Patching cracks and joints in firebacks, chimineas, and solid fuel boilers

Industries Served

- Fireplace and stove manufacturers

- Heating appliance installation contractors

- Building and construction suppliers

- Chimney and flue service professionals

- Home renovation and restoration firms

By combining tradition with modern materials engineering, Vitcas heat resistant products provide long-lasting performance, safety, and energy efficiency for the fireplace and stove market.