Silica-Based Refractory Mortars

Silica refractory mortars and adhesives for high-temperature applications

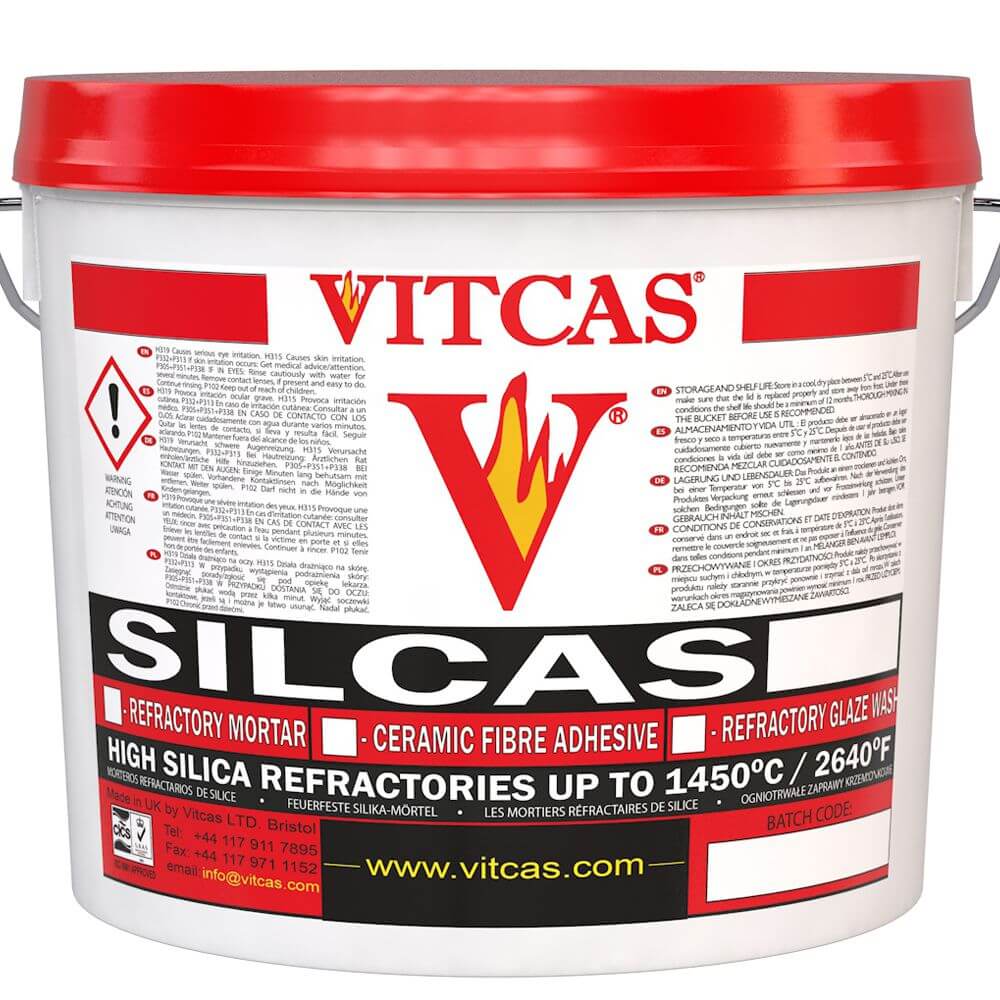

Vitcas® offers a comprehensive range of silica-based refractory products developed for demanding industrial high-temperature environments. This line includes mortars, adhesives, repair cements, glaze washes, and technical coatings designed for use with silica bricks, ceramic fibres, and monolithic refractory structures. All products provide excellent bonding strength, chemical compatibility, and thermal resistance in furnaces, kilns, incinerators, regenerators, and other areas subject to thermal and mechanical stress.

Silcas A – Ready Mixed Refractory Mortar

Silcas A is a silica-based, ready-mixed, air-setting refractory mortar designed for setting and jointing both insulating and dense firebricks. It is rated for service temperatures up to 1400°C (2550°F) and offers excellent bonding strength, thermal stability, and ease of application in a variety of high-temperature environments.

Examples of Applications: Silcas A is used in kiln and furnace side walls constructed from special shapes or conventional bricks, as well as in furnace and kiln roofs made from arch bricks. It is suitable for smaller kiln cars subjected to low thermal and mechanical stress, including kiln car decks assembled from jointed pre-fired blocks. The mortar is also ideal for general refractory repair work, including the installation of burners, peep-hole blocks, and thermocouples.

Silcas S – Silica Mortar for Silica Bricks

Silcas S is a high-purity, air-setting silica-based refractory mortar specifically formulated for use with silica bricks. It provides excellent chemical compatibility, bonding strength, and thermal stability, ensuring reliable performance at elevated temperatures. The mortar is designed to match the thermal expansion characteristics of silica refractories, minimising stress and extending service life in demanding environments. It offers a maximum service temperature of up to 1550°C, making it ideal for use in high-temperature industrial processes where silica refractories are required.

Examples of Applications: Silcas S is used for laying and jointing silica bricks in coke ovens, glass tank regenerators, acid regeneration units, and other high-temperature installations where the structural integrity and chemical compatibility of silica-based materials are essential. It is also suitable for repairs and maintenance of existing silica linings in furnaces and regenerators, where consistent thermal performance is required.

CFA - Ceramic Fibre Adhesive

Ceramic Fibre Adhesive - CFA is a silica-based, high-temperature, air-setting adhesive and coating designed for use with ceramic fibre products. It is suitable for bonding ceramic fibre modules, blankets, boards, and laminates to refractory surfaces such as brickwork or steel. The adhesive should be applied directly to the refractory or metal substrate rather than to the fibre surface. When used as a surface coating, it can be diluted with water to provide a protective layer against high gas velocities or molten metal splash. The maximum service temperature is 1260°C (2300°F), making it ideal for use in high-temperature thermal insulation systems.

Examples of Applications: CFA is used for bonding ceramic fibre products to refractory linings in furnaces, kilns, and incinerators, as well as for securing modules and boards onto steel casings or brickwork. It is also applied as a protective coating over ceramic fibre surfaces to reduce erosion in areas exposed to high-velocity gases or molten metal, such as in petrochemical processing, foundries, and steelworks.

Silcas M - White Ready Mixed Refractory Mortar

Silcas M is a white, silica-based, ready-mixed, air-setting refractory mortar formulated for setting and jointing insulating fire bricks and for use as an adhesive in high-temperature applications. It is especially suited to situations requiring a clean appearance and strong thermal performance. With a maximum service temperature of 1425°C (2600°F), Silcas M is ideal for both refractory construction and specialist industrial processes involving high heat and insulation.

Examples of Applications: Silcas M is used for setting and jointing all types of insulating fire bricks in kilns, furnaces, and high-temperature chambers. It is also widely used in the precision casting industry, particularly in the investment casting lost wax process, where it serves as an effective adhesive for bonding ceramic fibre blanket to ceramic shells.

Silcas HP – High-Temperature Hot Patch Repair Cement

Silcas HP is a high-performance, silica-based hot patch repair cement designed for sealing and repairing refractory structures exposed to high thermal and mechanical stress. It is especially formulated for use in environments where frequent maintenance is required, offering strong adhesion and durability under operating temperatures up to 1430°C (2600°F). The material sets upon exposure to heat, making it ideal for in-service repairs without the need for shutdown.

Examples of Applications: Silcas HP is primarily used for repairing and sealing door jambs in coke ovens, as well as for repairing foundry ladles and launders in non-ferrous foundries where the operating temperature does not exceed 1430°C. It is suitable for patching high-temperature contact areas that require quick, heat-setting maintenance solutions.

Silcas SR – Refractory Cement for Hot Repair of Coke Oven Soles

Silcas SR is a dry, silica-based refractory cement specifically developed for in situ hot repair of coke oven soles. It is mixed on-site with water and pumped directly into the oven, where it can be spread along the sole using the recoke push bar and allowed to self-level. The material offers excellent flowability, rapid setting under heat, and strong adhesion to existing refractory linings. It is rated for service temperatures up to 1400°C (2550°F) and enables effective maintenance without full shutdown.

Examples of Applications: Silcas SR is used for hot repairs of worn or damaged soles in coke ovens, particularly during continued operation. Its self-levelling properties and ability to be pumped in and applied through standard push bar techniques make it ideal for fast maintenance in high-temperature, high-wear areas of the oven floor, extending service life and minimising downtime.

Silcas RGW – Refractory Glaze Wash

Silcas RGW is a refractory glaze wash designed for application to brick and monolithic linings to enhance surface protection and reduce dusting and erosion. With a maximum service temperature of 1000°C (1830°F), it forms a durable glaze that improves resistance to gas velocities and mechanical abrasion. The thixotropic consistency allows for application by brush, spray, or trowel, although brushing is recommended to ensure strong bonding and an integral surface layer. For optimal performance, the coated lining should be heated to 1000°C on the first firing to fully vitrify the surface.

Examples of Applications: Silcas RGW is used to coat the surfaces of refractory linings in kilns, furnaces, incinerators, and chimneys, especially in applications requiring reduced dusting, smoother surfaces, and improved wear resistance. It is ideal for extending the life of firebrick and castable linings in areas exposed to moderate temperatures, gas flow, and abrasion, and is commonly used in the ceramics, waste processing, and thermal engineering industries.